CHONBURI

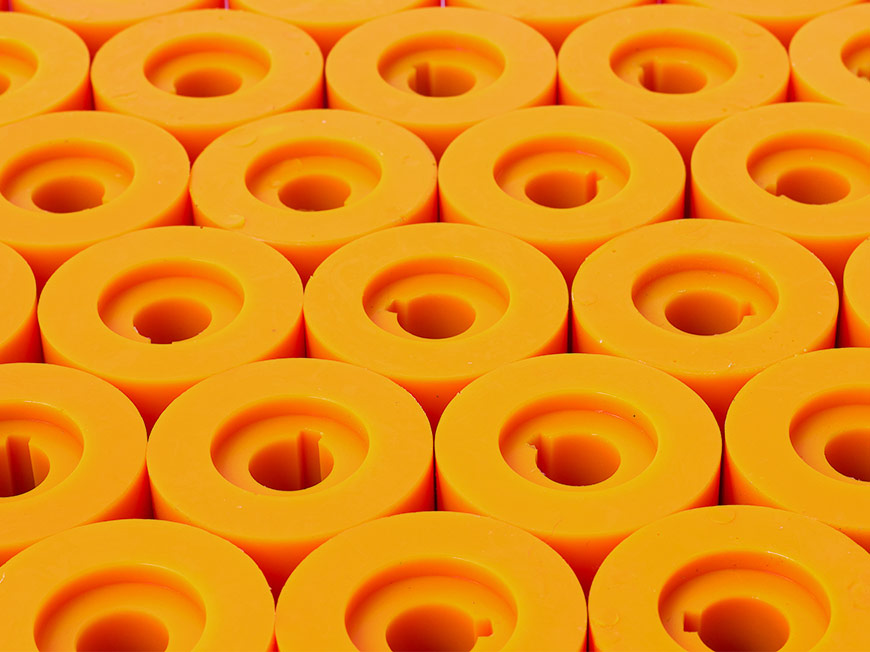

Polyurethane Industry

Background

The challenges faced by the Polyurethane industry

Moisture is one of the primary challenges in the polyurethane industry since the material readily absorbs water from the air and create gaseous carbon with the isocyanate constituent. The Carbon Dioxide gases can create undesirable effects such as air bubbles on polyurethane coating, which significantly decreases the shelf life of the product.

Controlling moisture can be difficult since numerous factors contribute to the humidity within the room such as heat and the number of people inside an enclosed area.

Solution

The application of activated zeolite powder to solve problems

- Our activated zeolite powders are an efficient moisture prevention solution that works on a molecular level. The powder blocks the formation of bubbles and foam within the area by stopping the reaction of the isocyanate group and free water. Pores within the activated zeolite powders also rapidly absorb almost all water molecules across a wide area.

- The protective moisture-prevention qualities of our activated zeolite powders are essential to protecting the quality of nearly any polyurethane products during the manufacturing process. Our zeolite powders do not require additional resources to use and are easy to incorporate with your manufacturing floor, helping you cut down production costs.

More Specific Industrial Applications

Anticorrosive coating & painting

- Active ingredients, including tin and zinc, of nearly all coating and painting products, react with moisture in the environment to produce hydrogen.

- By utilizing our 4A molecular sieve, clients can prevent dangerous water reaction to the active ingredient of coatings and paints. Our activated zeolite powder can improve the uniformity and strength of polyurethane products and other similar materials by stopping the formation of air bubbles.

Specific polymers

Various commercial polymers are hygroscopic and absorb water molecules, creating cosmetic defects on the material’s surface. Our activated zeolite powder rapidly absorbs most of the moisture in the area as well as by-product gases such as CO2 and SO2 to preserve the look of hygroscopic polymer products.

Adhesives and sealants

The tackiness of adhesives and sealants can be compromised by exposure to moisture that comes from foam formation. Prevent water molecules from affecting the performance of most polyurethane products with our 3A active zeolite powder that absorbs most moisture content in the room and prevents foam generation.

Deep dehydration of pigments and solvents

Removing most of the moisture from pigments and solvents can prolong the original particle size and pigment value of the polyurethane products. Our activated zeolite powder fully absorbs various impurities for deep dehydration of moisture-sensitive formulas such as pigments and solvents.

.

Contact Us

JALON MICRO NANO NEW MATERIALS CO. LTD

NO. 890/68 Moo 3, KHAO KHANSONG, SI RACHA, CHONBURI - 20110, Thailand

Mobile : +66-971585837224

E-mail : himanshu.sharma@jalonzeolite.com